Notes:

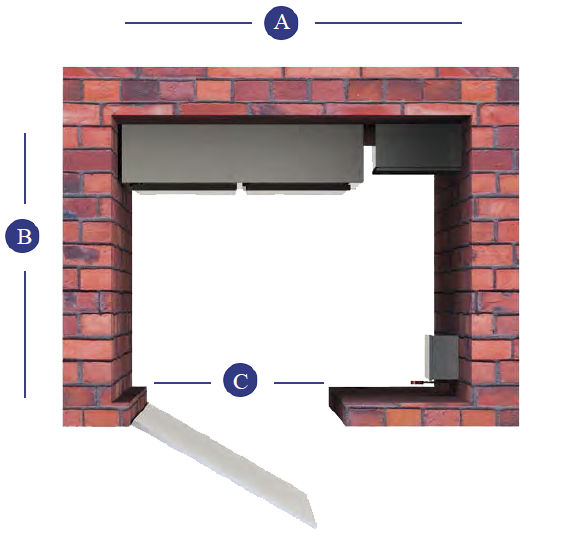

- Provide a legally constructed and enclosed control room, adequately lighted, and conditioned to maintain temperature between 32° to 104° Fahrenheit, relative humidity is not to exceed 95% non-condensing.

- Control room must be of adequate size to provide clearances around and between equipment as required by code.

- Provide a fused disconnect switch for each elevator in the control room, located in a position based on local code and within sight of elevator equipment, and arranged to be locked in the off position.

- Provide 110 VAC service for elevator light and accessories connected to the car light service terminal on the elevator controller. A single disconnecting means for the car light and accessories shall be located in the control room and arranged to be locked in the open position.

- Provide light, switch and 110 VAC GFI outlet in the control room, with switch located adjacent to the door.

- Only elevator related equipment is allowed inside the control room.

- Dimensional data shown above may vary from National Codes to Local Codes.

- For Duplex or Triplex applications control rooms will have different dimensions. Consult your sales representative.

- When special equipment is required, as transformers, brake resistors, etc sizes of control room will increase to accommodate the equipment and have the required clearances. This factor determine the Small / Large size of the Control Room.

- Transformers, resistor boxes and similar equipment are required to have 6” clearances on all sides.

- NEC work space minimum clear distances vary from 3 to 4 feet depending on nominal voltage and mounted electrical equipment condition, consult your AHJ.

- The preferred location of the Control Room is adjacent to the hoist way on the top floor, but other locations could be used. The linear maximum run of the encoder communication cable is 160 ft., from the machine to the controller.

Governor Access:

- Determine if your Local code allows remote rest governor, if not an access up on the overhead must be provided to inspect and reset the governor. If it is not possible to provide an access up on the overhead an option will be the use of a Delaware Pit Mounted Governor.